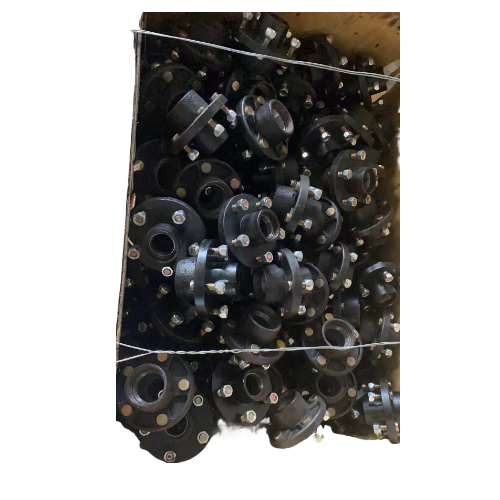

5 Stubs Trailer Axle Hubs with Spare Parts

1. Durability: Trailer hubs are designed to withstand heavy loads and provide long-lasting performance. They are typically made from high-quality materials like steel or aluminum, which are resistant to corrosion and wear.

2. Easy installation: Trailer hubs are relatively easy to install, especially if you have some basic mechanical skills. They typically come with clear instructions and can be easily mounted onto the trailer axle.

3. Smooth towing: Trailer hubs are designed to provide a smooth and stable towing experience. They typically include high-quality bearings that allow for easy rotation and reduce friction, resulting in smoother and more controlled towing.

4. Maintenance: Trailer hubs are relatively low-maintenance compared to other trailer parts. Regular maintenance, such as greasing the bearings, can help ensure optimal performance and prolong the lifespan of the hubs.

5. Versatility: Trailer hubs are available in various sizes and configurations to fit different types of trailers. This makes them a versatile option for a wide range of towing needs.

Trailer Hub Features:

1. Bearings: Trailer hubs typically have high-quality bearings that allow for smooth rotation of the trailer's wheels. These bearings are often sealed to prevent water and dirt from entering, providing increased durability.

2. Grease fittings: Some trailer hubs have grease fittings, which allow for easy lubrication of the bearings. Greasing the bearings regularly helps to maintain optimal performance and extend their lifespan.

3. Dust caps: Dust caps are installed on the hub ends to protect the bearings from debris, moisture, and other contaminants. They help to keep the bearings clean and functioning properly.

4. Brake compatibility: Many trailer hubs are designed to work seamlessly with trailer brakes. They may have bolt patterns or mounting features specifically for attaching brake assemblies, making them suitable for trailers that require braking capability.

5. Lug patterns: Trailer hubs have lug patterns that match the wheels they are intended for. Common lug patterns include 4-lug, 5-lug, or 6-lug designs. The lug pattern determines the number of bolts needed to secure the wheel to the hub.

6. Pre-greased options: Some trailer hubs come pre-greased from the manufacturer, saving you time and effort during installation. These hubs are already lubricated and ready for use.

7. Weight capacity: Trailer hubs are rated to handle specific weight capacities. It is important to choose a hub that matches the weight rating of your trailer, ensuring safe and reliable operation.

8. Easy installation: Trailer hubs are typically designed for easy installation and replacement. They often come with installation instructions and include all the necessary hardware for mounting.

How to use a trailer hub?

1.Safety first: Before starting any work on the trailer hub, make sure the trailer is securely supported and parked on a level surface. Use wheel chocks to prevent it from rolling.

2.Remove the old hub: If you need to replace the trailer hub, start by removing the wheel and tire. Then, use a wrench or socket to remove the bolts or nuts that hold the hub in place. Pull the old hub off the axle spindle.

3.Inspect and clean the axle spindle: Take a close look at the axle spindle for any signs of damage, wear, or corrosion. If you notice any issues, consult a professional for further inspection. Clean the spindle thoroughly using a wire brush or sandpaper to remove any dirt or debris.

4.Prepare the new hub: Before installing the new hub, make sure it is the correct size and specifications for your trailer. Apply a thin layer of grease on the inside of the hub to provide lubrication.

5.Install the new hub: Slide the new hub onto the axle spindle, making sure it fits properly. Align the hub's mounting holes with the ones on the spindle. Insert the bolts or nuts and tighten them securely.

6.Apply proper torque: Use a torque wrench to tighten the bolts or nuts according to the manufacturer's specifications. Over-tightening can cause damage, while under-tightening can result in a loose hub, leading to accidents and additional wear.

7.Install the wheel and tire: Place the wheel and tire back onto the hub, making sure the lug nuts or bolts are secure. Use a torque wrench to tighten them to the recommended specifications.

8.Test the hub: Once everything is properly installed, remove the wheel chocks and take a short test drive at a low speed. Pay attention to any unusual noises or vibrations. If you notice any issues, stop and inspect the hub again or consult a professional.